Research Article

Improvement of Coffee Bean Quality by Using Saccharomyces Cerevisiae and Pectinase During the Drying Process

4931

Views & Citations3931

Likes & Shares

Vietnamese Robusta coffee has been mainly processed by drying method which allows natural fermentation of the fruit’s pulp and mucilage to occur during drying period. The reliance on natural microorganisms may cause negative effect on the coffee bean quality. Therefore, the aim of this work was to evaluate the potential of the use of S. cerevisiae and pectinase for Robusta coffee in dry process. In this study, Robusta coffee was inoculated with S. cerevisiae and pectinase with different doses/ kg fresh cherries as following: 1g yeast; 3g yeast, a combination of 1 g yeast and 0.2g enzyme; a combination of 3g yeast and 0.2g enzyme. The control was without any selected yeast and enzyme. The fruits were incubated for 4 days before sun drying. During incubation, the temperature inside the mass was recoded and samples were collected for determining bacterial and yeast population. During drying, samples were collected for evaluation of the moisture contents of coffee bean, physical and cup testing. The results show that, in all tests, the number of yeast and bacteria was higher than the control. The moisture contents of coffee bean in all treatments came down quicker than in the control. The physical and cup testing of coffee beans in all treatments seen to be better than in the control. The combination of 3g yeast and 0,2 g pectinase per 1 kg coffee cherries was the best treatment for Robusta coffee fermentation in dry process because this treatment had high number of bacteria and yeast (3.59x106 cfu/g and 31.41x104 cfu/g, respectively), high cup-testing score (71.8) and low percentage of defects (1.47%).

Keywords: Robusta coffee, S. cerevisiae, Pectinase, Dry processing, Coffee drying

INTRODUCTION

Coffee is an important Vietnam commercial product (approximately 1.6 million tone/year) with its consumption distributed globally. Vietnam is the leading producer and exporter of coffee Robusta. However, the benefit from this commodity is still lower than the same product in other countries because of the low and unstable quality.

Before coffee cherries can be traded and processed into a final industrial product, they have to undergo postharvest processing on farms to become green coffee beans, which have a direct impact on the cost and quality of coffee beans. Commonly, there are three different methods used for transforming the fresh coffee cherries into the dried green beans, known as wet, dry and semi-dry methods [1]. In Vietnam, the dry process has been widely used for Robusta coffees (about 90%). During this process, the intact coffee fruits are sun-dried on the coffee drying patio in a 5-10cm thick layer for 10-20 days, depending on weather conditions, until the moisture content reaches 12% - 13%. Fermentation of the pulp and mucilage within the fruit occurs during this period [2]. Sugars and pectin present in the mucilage will allow microorganisms’ growth. In natural or drying processing, the microorganisms responsible for the fermentation are bacteria, yeasts and filamentous fungi, all of which predominate in the fruits [3]. The fermentation contributes to the production of alcohols, organic acids (acetic, butyric, lactic and propionic acids) and other metabolic compounds that can interfere in the organoleptic quality of the beverage [1-3]. However, the reliance on natural microflora in coffee cherries for fermentation may give rise to inconstant and uncontrollable issues, negatively affecting the quality of coffee beverage. Therefore, the use of starter cultures (selected microorganisms) can improve the quality of coffee beans and the sensory quality of the final beverage by providing better fermentation control and predictability of the final product.

According to study of Silva [4], the Saccharomyces cerevisiae has good potential to be used as starter cultures for coffee fermentation. Their pectinolytic enzymes secretion hydrolyses the coffee mucilage, improving the quality of the fermentation process. Besides, the authors showed that the production of organic acids and volatile compounds by those yeasts might contribute to the coffee final quality. Therefore, in the present study, Saccharomyces cerevisiae and pectinase was used during coffee incubation before drying to improve the quality of coffee Robusta.

MATERIALS AND METHODS

Materials

Coffee cherries: Robusta coffee cherries from WASI were used. They were harvested by manual picking with over 70% ripened fruits (red fruits).

Methods

Inoculation of starter culture and enzyme: The coffee cherries (500kg/treat) were spread from 15-20cm thick on concrete patio and each treatment was inoculated separately with the different doses of S. cerevisiae and pectinase as following:

- The control: without any yeast and enzyme

- Treatment 1 (Treat1): with 1g yeast per 1kg coffee cherries

- Treatment 2 (Treat2): with 3g yeast per 1kg coffee cherries

- Treatment 3(Treat3): with 1g yeast and 0,2 g enzyme per 1kg coffee cherries

- Treatment 4 (Treat4): with 3g yeast and 0,2 g enzyme per 1kg coffee cherries

(There is about 108-109CFU yeast/g)

All coffee cherries were mixed well, then pile up to incubate for 4 days and then sun dried until they reach 12-13% of moisture. During piling up and drying, samples were collected aseptically, placed in sterile plastic bags and transferred to the WASI lab for microbiological, physical and sensory analyses.

Mass temperature determination during incubation: The temperature of coffee cherry mass was determined by

using a temperature meter (HANA). The probe of the temperature meter was placed into the middle of the coffee cherry mass, taken at 5 different points of the mass of each treatment.

Study of the kinetic of drying: The study of the kinetics of drying was carried out by determining the daily moisture content of coffee cherries during drying. The method used followed the procedure of Kouadio. Coffee cherries were dried in an incubator at 1050C until constant weight. The weight lost is calculated.

Enumeration of microorganisms: Each sample (20 g of fruits) was added to a bottle containing 180 mL of peptone water and gently shake for 20 min. After that ten-fold dilutions were prepared. Microorganisms were counted using 2 different culture media:

- PCA agar: was used as a general medium for the viable bacteria population

- Dicloran glycerol (DG18) agar was used for yeasts

Following inoculation, the plates were incubated at 280C for 48h for Bacteria and 5 days for yeast. Then colony-forming units (CFUs) were counted, and the population was estimated as the CFU per gram of fermented coffee cherries.

Green coffee bean quality determination: The determination of green coffee beans followed TCVN 4193:2014.

Analysis of sensory characteristics: The sensory evaluation was conducted according to SCAA standard, assessing ten sensorial attributes: fragrance, flavor, after- taste, acidity, body, uniformity, balance, sweetness, cleanliness and score.

Time and location of study: The experiment was conducted in Robusta coffee season of 2018 (from October to December 2018) at Wasi, Buon Ma Thuot, Daklak.

Statistical analysis: Results were statistically analyzed with the Minitab 2016 program, using one-way analysis of variance (ANOVA). The significance of the difference between means was determined by Duncan’s multiple range test (P-values <0.05).

RESULTS AND DISCUSSION

Temperature variation in the cherries mass during incubation

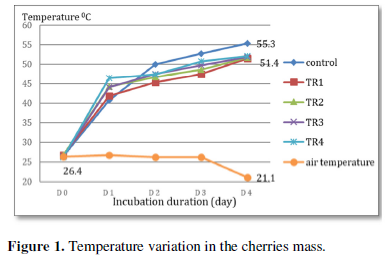

The variation of temperature inside the cherry’s masses during 4-day fermentation was presented in Figure 1. The ambient temperature varied between 21.1°C and 26.4°C.

As the results was showed on the Figure 1, the temperature of all coffee cherries masses was higher than ambient temperature during the whole time of incubation. After 24 h incubation, the temperature inside the mass of all treatments and the control increased significantly from around 260C to over 500C. The increase of temperature may come from the growth of microorganisms and the respiration of coffee cherries. After the first day of incubation, the control had lowest temperature (40.70C) while the temperature inside coffee cherry mass of TR4 was the highest (46.5°C).

After 4 days incubation, the temperature inside the mass of all treatments and the control went up dramatically and reached the highest point. The highest temperature was observed in the control (55.50C). However, there was not significantly different between treatments in terms of the coffee cherry mass temperature which varied between 51.4°C and 52.1°C. The high temperature in the coffee mass can accelerate the fermentation process. However, according to Alves et al (2017), coffee mass temperature higher than55°C causes thermal damage that depreciates coffee bean quality. Thus, natural incubation of coffee cherries might cause more negative effect on the coffee quality than using selected yeast and enzyme as it increased the temperature of the mass up to 55.5°C which was higher than that of treatments.

After 4 days incubation, the temperature inside the mass of all treatments and the control went up dramatically and reached the highest point. The highest temperature was observed in the control (55.50C). However, there was not significantly different between treatments in terms of the coffee cherry mass temperature which varied between 51.4°C and 52.1°C. The high temperature in the coffee mass can accelerate the fermentation process. However, according to Alves et al (2017), coffee mass temperature higher than55°C causes thermal damage that depreciates coffee bean quality. Thus, natural incubation of coffee cherries might cause more negative effect on the coffee quality than using selected yeast and enzyme as it increased the temperature of the mass up to 55.5°C which was higher than that of treatments.

Microbiological analyses

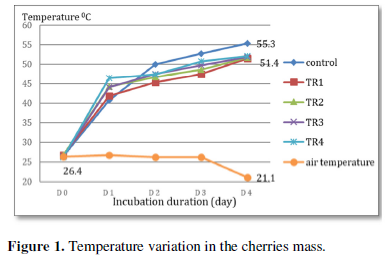

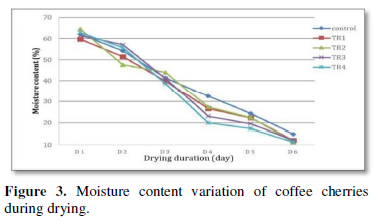

The population of bacteria and yeast during the incubation of the four treatments and the control (without inoculum) are shown in Figure 2. In general, bacterial numbers were higher than yeast numbers during the fermentation. The control had low bacterial and yeast populations compared to the other treatment, reaching maximum values of 2.15 x 106 cfu/g and 9.91 x 104 cfu/g, respectively, after 96 hours incubation. It is observed that the bacterial numbers in most treatments and the control increased significantly during the entire fermentation process, reaching the highest value after 96h incubation, except for treatment 3 where the bacterial count reached the maximum value of 3.21 x 106 cfu/g after 48h incubation. The highest number of bacteria was observed for treatment 4 with 3.59 x 106 cfu/g on the fourth day of the fermentation process.

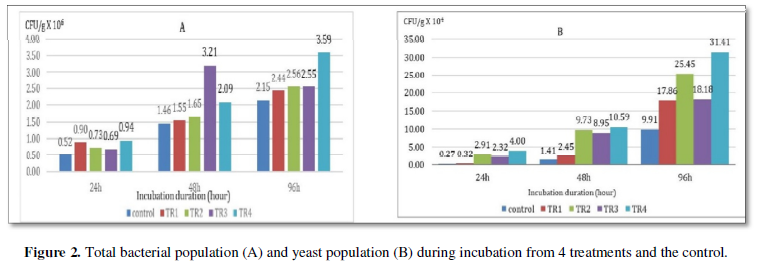

The variation of coffee cherry moisture content during drying

The results showed on Figure 3 shows the decrease of coffee cherries moisture contents of four treatments and the control during drying. It was noticed that the initial water content of coffee cherries after 4 days incubation varied from 59.78% to 64.56%. It took 6 days to decrease those moisture contents to under 15%. The result shows that the coffee cherries in all treatments dried faster than the control. For instance, after 6 day drying, the coffee cherries in all treatments dried to the moisture content of around 11%, while the control cherries still remained 15.01% moisture. This may be because that the high bacterial and yeast population in treatments broken down the coffee cherry cell wall more significantly than in the control, accelerating the seed moisture removal rate. The decrease in moisture contents between treatments showed no significant differences during drying. However, it was possible to observe that using high dose of yeast seen to make coffee cherries dry faster. For instance, after the same drying duration (6 days), the moisture level for coffee cherries in Treat 1 and Treat 3 (using 1g of Yeast/kg cherries) was 11.97% and 12.15%, respectively, which was higher than cherries moisture in Treat2 (11.26%) and Treat 4 (11.25%). This was already expected due to the presence of the high microbial population in Treat 2 and Treat 4.

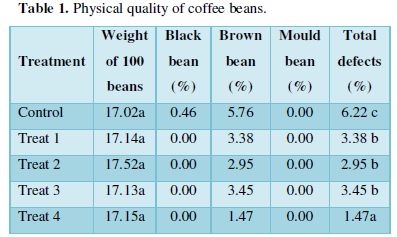

PHYSICAL AND SENSORY QUALITY OF COFFEE BEAN

The physical quality of coffee beans from four treatments and the control was presented in Table 1. As seen from the table, the highest percentage of defects was seen in the control with 6.22%, while treatment 4 had the lowest ratio of defects (1.47%). This is due to the high temperature inside the control mass during incubation which might cause negative effect on the color of coffee beans. The result also showed that there was not presence of mould on coffee bean and the weight of 100 beans of all treatments were not significantly different from the control. Although there was presence of defects in green coffee beans, the percentage of defects in all treatments and the control was still low.

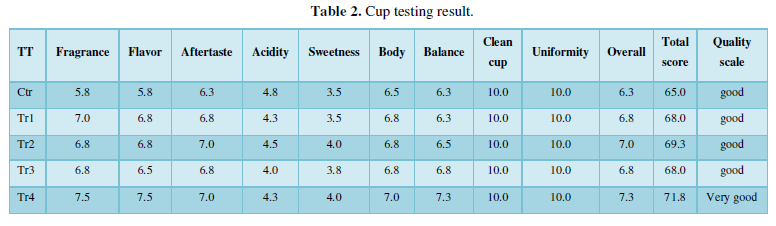

The total scores of the cupping test for all treatments ranged from 68 to 71.8 which was higher than that of the control (65), especially treatment 4 with the highest total scores of 71.8 (Table 2). The selected yeast inoculated in these treatments may lead to an increase of volatile compounds in roasted coffee which could contribute to improve the sensory quality of the final beverage. S. cerevisiae used in this study as starter culture was reported in a previous work as producer of pectinolytic enzyme which aided in the degradation of the pectin present in coffee pulp and mucilage (Evangelista, 2014). The products of fermentation process such as organic acid may diffuse into the interior of the coffee beans, favoring the formation of the flavor of the final beverage. Therefore, the inoculation of yeast and enzyme to the coffee cherries mass can improve the sensory quality of coffee beans.

CONCLUSION

In all treatments, the bacterial and yeast population were higher than in the control, especially TR4 with 3.59x106 cfu/g bacteria and 31.41 x104 cfu/g yeast. The coffee cherries in all treatment seen to be dried faster than in the control. After 6 day drying, the moisture content in all treatments decreases under 12%, while the coffee cherries in the control still remained 15.01% moisture. Sensory and physical quality of coffee beans in all treatments was better than that of the control, especially coffee bean in TR4 with low defect value (1.47%) and high score of cup testing (71.8). It was possible to conclude that S. cerevisiae and pectinase should be used for the fermentation of Robusta coffee in dry processing. The inoculated yeasts could persist during the entire fermentation, be able to compete with natural microorganism present in the coffee cherries and be able to use coffee pulp as substrate, which resulted in accelerating the moisture removal rate during drying and improving physical and sensory of coffee beans. Treatments 4 with the combination of 3g yeast and 0,2 g pectinase per 1 kg coffee cherries was the best treatment as coffee cherries in this treatment dried faster and had higher physical and sensory quality.

- Haile M, Kang WH (2019) The Role of Microbes in Coffee Fermentation and Their Impact on Coffee Quality. J Food Qual 2019: 1-6.

- Evangelista SR, Silva CF, da Cruz Miguel MGP, de Souza CC, Pinheiro, et al. (2014) Improvement of coffee beverage quality by using selected yeasts strains during the fermentation in dry process. Food Res Int 61: 183-195.

- Schwan RF, Silva CF, Batista LR (2012) Coffee Fermentation, Handbook of Plant-Based Fermented Food and Beverage Technology. CRC Press. pp: 1-821.

- Silva CF, Vilela DM, de Souza CC, Duarte WF, Dias DR, et al. (2013) Evaluation of a potential starter culture for enhance quality of coffee fermentation. World J Microbiol Biotechnol 29(2): 235-247.

QUICK LINKS

- SUBMIT MANUSCRIPT

- RECOMMEND THE JOURNAL

-

SUBSCRIBE FOR ALERTS

RELATED JOURNALS

- Journal of Biochemistry and Molecular Medicine (ISSN:2641-6948)

- Journal of Veterinary and Marine Sciences (ISSN: 2689-7830)

- Journal of Womens Health and Safety Research (ISSN:2577-1388)

- Advances in Nanomedicine and Nanotechnology Research (ISSN: 2688-5476)

- Journal of Agriculture and Forest Meteorology Research (ISSN:2642-0449)

- Journal of Genomic Medicine and Pharmacogenomics (ISSN:2474-4670)

- Proteomics and Bioinformatics (ISSN:2641-7561)