1320

Views & Citations320

Likes & Shares

Equipment represents a major capital investment in food services, for example technological and operational significance. Equipment design affects food safety and quality as well as energy consumption; equipment layout is linked to sanitation, productivity and capital costs. The studies in this filed range from simple temperature profiling to computer-based simulations (Bourke and Bates, 2015 and Bryant, 2016).

Typically, different heating methods (convection, radiation, conduction, induction, etc.) are evaluated and the quality of the final product is used as a main criterion (Van Son, 2017). The geometrical design of a unit, the loading of the product and its shape affect the heat penetration. The improved ways of temperature measurement/recording and equipment “cleanability” supporting HACCP and GMP (good manufacturing practices); comparisons of energy use between the systems (Thomas and Brown, 2017; Verboven et al., 2018). The food service sector has a significant impact on future packaging developments (Brody, 2018). Packaging material suppliers have developed technologies to deliver LSL (Long Shelf-Life). Generally, the research on equipment and packaging leads to better control of processing/storage conditions and, consequently, to higher operational efficiency and food quality (Dobias et al., 2019).

Operational efficiencies drive the application of “hard” or equipment-based technologies. Generic operations management concepts such as productivity, capacity and bottlenecks, master production scheduling, benchmarking and supply chain management are applicable to food services. The mathematics/statistics used in this field ranges from the relatively simple empirical formulas estimating the number of “meal equivalents” or equipment capacity, for example, to such sophisticated techniques as data-envelopment analysis or simulation models(Reynolds, 2019).

- To review the applied research in food services and the technical literacy needed to interpret and benefit from it.

- To investigate food quality management, Efficiencies through extended shelf-life.

- To evaluate equipment and packaging design, consumer and market studies and Implications for educators.

- To study the educational needs to improve the food service.

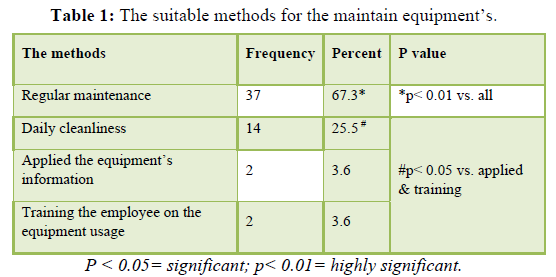

The conducted interviews pointed out that there is a highly significant between regular maintenance vs. all devices (p< 0.01) (Table 2). On the other hand there is a significant between Daily cleanliness and both devices “Applied the equipment information and Training the employee on the equipment usage” (p<0.05).

p< 0.001= extremely significant.

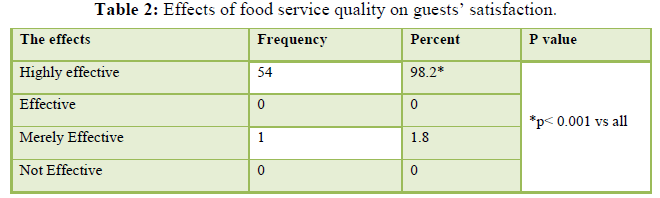

Tabulated data revealed that the majority of answers were highly effective (98.2). while there is only (1.8%) of all respondents mentioned that merely effective. The study showed that the highly effective answer is a significantly high compared to all answers, p

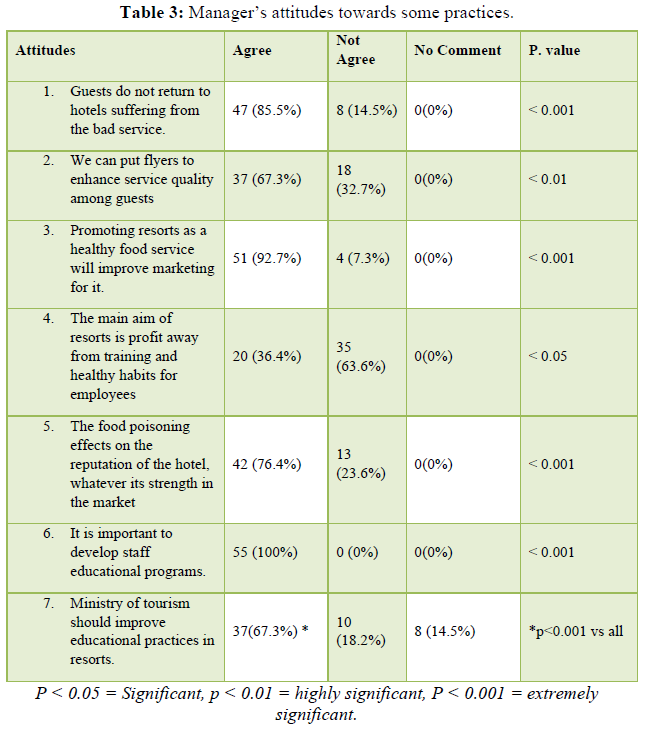

The results illustrated that, in the attitude number one in Table 3, (85.5%) of the respondents ensured that most guests do not return to hotels, because suffering from the bad service, while (14.5%) mentioned that this point is not enough to effect on guest satisfaction. It is observed that there is an extremely different significant between the managers who agree and who don’t agree "p < 0.001".

In the attitude number two, (67.3%) of the respondents referred to that we can put flyers to enhance service quality among guests, rest (32.7%) stated that is not important to increase guest’s awareness. The study indicated that there is a highly significant between the different manager’s attitudes, p< 0.01.

On the other hand, the results showed that attitude number three referred to majority of the respondents (92.7%) ensured that promoting resorts as a healthy food service will improve marketing for it. But only rest (7.3%) stated that the promoting about healthy food service it isn’t necessary to improve the marketing process in resorts. Further analysis of the profile of respondents in the investigated sample, indicated that the highest percentage was found in “agree” when compared with “not agree”. There is an extremely significant between the different answers, p< 0.001. Answers of the collected questionnaires revealed that the attitude number four, (36.4%) only of the respondents referred to that The main aim of resorts is profit away from training and healthy habits for employees, while (63.6%) of them declared that the main aim for most resorts is profit only. Hence, the study showed that the percentage of managers who don’t agree was higher than the percentage of agree, p< 0.05.

Tabulated data revealed that (76.4%) of the respondents illustrated that the food poisoning affects the reputation of the hotel, whatever its strength in the market, but (23.6%) of them doesn’t agree on this attitudes, depended on the hotel’s image and his reputation in the market. it is observed that there is highly significant difference, p

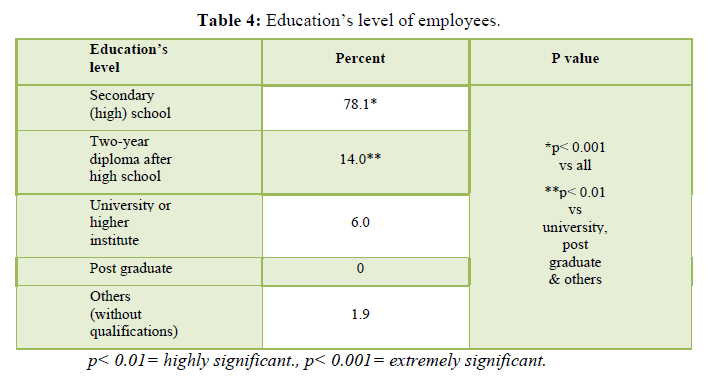

From the results shown Table 4, it could be noticed that the respondents stated that lack of the money and time items is very big problem hinder the training and educational program, and to that most of the resorts depending on the employee’s experience. The obtained results revealed that most of the respondents referred to that the HACCP system is apply in their hotel, while only little mentioned that Food Safety risk management (FSRM) system is apply in their hotel.

From the answers presented in table 4, it could be seen that, secondary (high) school had the highest percentage which represents (78.1%) of all respondents. A further (14%) had a two-year diploma after high school. Some (6%) were university or higher institutes, a low percentage (1.9%) of respondents were without qualifications. The study also showed that there were nobody of the respondents had post graduate. Resort's employees who received university or higher institute education were less prominent than other education levels, p< 0.001. On the other hand, the study indicates that there is highly significant between the employees who had two-year diploma after high school and “university or higher institute”; “others, without qualifications”, p< 0.001.

Conclusions and Future Research Implications

Research on food services represents a large body of scientific knowledge supporting food safety (preservation principles and HACCP-related practices), food quality, equipment (design, layout and process control), facility design, operational management (benchmarking, food service system evaluation and modeling) and product-focused marketing. Technical literacy develops intellectual capabilities of graduates to operational efficiency from physical resources by applying a variety of hospitality quality service.

The concepts underpinning the studies reviewed in this paper are indicative of the scope and depth of the technical knowledge needed for understanding and benefiting from applied research available in the field. The practical classes on restaurant operations, which are praised as being industry-oriented and criticized as being craft-based (Cooper et al., 2019), can be conceptually strengthened with the well established fundamentals of science. The associations with the fundamentals of food production, food safety and quality management, product development, food commodities and purchasing, kitchen planning and equipment design should be made to improving the food service in hospitality industry. The advances in computer modeling and simulations can reduce the amount of physical resources needed, the laboratories from other departments can be utilized – food science, sensory, microbiology and engineering. Furthermore, food service equipment suppliers are often willing to provide their showrooms for educational purposes. Hospitality trade shows regularly held in major cities can be used as a “laboratory” to explore the latest trends in food service equipment and systems design. Fundamentally, operations include technologies and practices (Hudson, 2019); learning practices without an understanding of technologies limits graduates’ abilities to transfer objective principles of underlying systems across different hospitality sectors and to innovate. Furthermore, scientific fundamentals support other critical areas of tourism and hospitality: facility management and design (engineering systems), housekeeping (equipment, chemistry of cleaning and infection control), spas and health tourism (human physiology), waste management (bio-degradation) and the wider role of technologies as contributors, creators, protectors and enhancers of tourism experience (Stipanuk, 2019).

In terms of future implications, it is suggested that more research work should come into sight to better assess the results of the current study and knowledge of necessary educational needs to improve the food service in Egypt. Additionally, future research work could be undertaken to identify the reasons for failing to develop the food service industry.

Recommendations

The study recommends that must be select the proper equipment and correct layout, also co-ordination between industry and enforcement authorities. Also the study recommends that avoiding the following: 1) Limited expertise in food safety and preservation. 2) Difficulties in temperature measurement and equipment calibration. 3) Unevenness of temperature distribution.4) possible breakdowns in operations. 4) Staff resistance to work in low temperature environment. 5) The study recommends that applying training and educational courses for employees to learn how to develop a food service via Technologies.

- Armstrong, G.A. (2019). Sensory quality and consumer acceptance of souse vide products during storage. Third European Symposium on Vide, Katholieke Universities, Leuven, Belgium, pp. 233.

- Bourke, J.R. & Bates, E.J. (2015). Health concerns ‘drive’ foodservice packaging. New Food 5(3), 80-2.

- Brody, A.L. (2018). Foodservice drives packaging developments. Food Technology 56(10), 78-80-86.

- Bryant, K. (2016). Moveable feast. Restaurant Business 102(19), 38-41.

- Buhaly, M. & Bordi, P. (2016). Development and sensory evaluation of a high-protein, vitamin-fortified fruit roll-up for children with cystic fibrosis. Foodservice Research International 14, 243-56.

- Creed, P.G. (2019). The potential of foodservice systems for satisfying consumer needs. Innovative Food Science & Emerging Technologies 2, 219-77.

- Creed, P.G. & Pierson, B.J. (2016). Sous vide – past present and future. Third European Symposium on Sous Vide, Katholieke Universiteit, Leuven, Belgium, 379-394.

- Cooper, C., Shepherd, R. & Westlake, J. (2019). Tourism & Hospitality Education, The University of Surrey, Guildford, 60-1.

- Covalli, S.B. & Salay, E. (2020). Food quality and safety control activities in commercial foodservice in the cities of Campinal (Sp) and Porto Alegre (Rs). Brazil, Foodservice Research International 14, 223-39.

- Dobias, J., Voldrich, M., Marek, M., Cherovsry, M. & Chudackova, K. (2019). Active packaging – immobilization of preservatives on/in polymer packaging. Third European Symposium on Sous Vide, Katholieke Universiteit, Leuven Belgium, p. 69.

- Dwyer, L., Forsyth, P., Rao, P. & Valerio, P. (2013). How price competitive is Australian tourism?”, Progress in Tourism and Hospitality Research, Proceedings of the Eighth Australian Tourism and Hospitality Research Conference, Queensland, Australia 17-29.

- Gi-Tae, K., Koo, K.M., Paik, H.D., Lyu, E.S. & Lee, D.S. (2021). Sous video processing of seasoned spinach soup. Food Service Technology 2(3), 131-138.

- Gray, J., Armstrong, G. & Farley, H. (2020). Opprtunities and constrains in the functional food market. Nutrition and Food Science 33(5), 213-218.

- Hauben, K. (2017). Sous vide cooking: state of the art. Third European Symposium on Sous Vide, Katholieke Universiteit, Leuven Belgium, pp. 12-27.

- Hudson, B. (2019). Industrial cuisine revised. Cornell Hotel and Restaurant Administration Quarterly 38(3), 81-87.

- Jelenikova, J., Vanhoutte, H., Voldich, M. & Martens, T. (2019). Optimisation of pre-cooking and extension of shelf-life for sous vide cooked meat”, Third European Symposium on Sous Vide, Katholieke Universiteit, Leuven, Belgium 267-280.

- Johnson, B. & Chambers, M. (2019). Foodservice bench marking: practices, attitudes, and beliefs of foodservice directors. Journal of the American Dietetic Association 100, 175-80.

- Jones, P. (2015). Finding the hospitality industry? Or finding hospitality school of thought? Journal of Hospitality, Leisure, Sport & Tourism Education 3(1), 33-45.

- Jones, P. & Lockwood, A. (2015). The Management of Hotel Operations, Continium, London. Kazarian, E.A. (1989), Foodservice Facilities Planning, Wiley, New York, NY 295-311.

- Lassen, A., Eriksen, H., Fall, M. & Hansen, K. (2019). Vitamin losses in vegetables processed by four different catering techniques. Third European Symposium on Sous Vide, Katholieke Universitei, Leuven Belgium 297-306.

- Lawn, J. (2016). Innovation. Food Management 39(7), 30-42.

- Lee, D.S., Shin, D.H. & Yam, K.L. (2020). Improvement of temperature uniformity in microwave-related rice by optimising heat/hold cycle. Food Service Technology 2(2), 87-94.

- MacLaurin, T.L. (2020). Food safety in travel and tourism. Journal of Travel Research 39(3), 332-3.

- Martens, T. & Nicolai, B. (2019). Computer-integrated manufacture of sous vide products: the ALMA case study. In Chazala, S. (Ed.), Sous Vide and Cook-Chill Processing for the Food Industry, Aspen Publication, Gaithersburg, MD. pp. 111-30.

- Mibey, R. & Williams, P. (2020). Food services trends in New South Wales. Food Service Technology 2(2), 95-103.

- Milford, P. (2021). CDC report: some food-borne illnesses down; salmonella up. National Restaurant News. Available online at: www.findarticles.com/p/articles/mi_m3190

- Miles, D.W. & Ross, T. (2018). Identifying and quantifying risks in the food production chain. Food Australia 51(7), 298-303.

- Moskowitz, H.R. (2018). Creating new product concepts for foodservice: the role of conjoint measurement to identify promising features. Food Service Technology 1(1), 35-52.

- Panisello, P.J. & Quantick, P.C. (2020). Technical barriers to hazard analysis critical control point (HACCP). Food Control 12(3), 165-73.

- Quality Assurance Agency for Higher Education. (QAAHE) (2018). Hospitality, Leisure, Sport and Tourism, Quality Assurance Agency for Higher Education, Gloucester, pp. 4-13.

- Ratchford, B.T. (2014). Has the productivity of retail food stores really declined? Journal of Retailing 79, 171-82.

- Redmond, G.A., Gormley, T.R. & Butler, F. (2018). Using ready-meals as carriers for nutraceuticals. Proceedings: New Functional Ingredients and Foods, Copenhagen, Denmark, pp. 1-6.

- Reynolds, D. (2019). Hospitality-productivity assessment using data-envelopment analysis. Cornell Hotel and Restaurant Administration Quaterly, April, pp. 130-7.

- Rodgers, S. (2019). Value adding with functional meals. Food Service Technology 4(4), 149-58.

- Rodgers, S. (2019). Selecting a food service system: A review. International Journal of Contemporary Hospitality Management 17(2), 157-69.

- Rosset, P., Morelli, E., Noel, V. & Poumeyrol, G. (2019). Launch of a protocol for assessing the efficacy of industrial dishwashers. Industries Alimentaries et Agricoles 118(12), 16-18.

- Rybka, S. (2018). Developing a HACCP plan for extended shelf life cook-chill ready-to-eat meals. Food Australia 51(9), 430-433.

- Rybka, S., Kailasapathy, K., Bergan, J., Poniman, S., Mikhail, S., Gunasekera, C., Lin, Y. & Ferraris, J. (2020). Storage characteristics of selected cook-chill meals with an extended shelf-life. Food Australia 53(5), 191-195.

- Rybka-Rodgers, S. (2017). Improvement of food safety design of cook-chill foods. Food Research International 34, 449-55.

- Schellekens, M., Martens, T., Riberts, T.A., Mackey, B.M., Nicolai, B.M., van Impe, J.F. & de Baerdermaker, J. (2019). Computer aided microbial safety design of food processes. International Journal of Food Microbiology 24(1), 1-9.

- Seo, S. & Shanklin, C. (2019). Assessing importance of food and service quality attributes of dining service in continuing care retirement community. Proceedings I-CHRIE Annual Conference, Philadelphia 295-300.

- Sheard, M.A. (2017). Marketing and technological competence: key to the development of the UK sous vide market. Third European Symposium on Sous Vide, Katholieke Universiteit,Leuven Belgium. 419-436.

- Skipnes, D., Bergslein, H., Rosnes, J.T., Vorre, A., Soyland, K. & Vidvei, J. (2019). Development of a sous vide production facility in Norway – Fjorkokken A.S. Third European Symposium on Sous Vide, Katholieke Universiteit, Leuven Belgium, pp. 438-453.

- Snyder, O.P. (2015). The application of HACCP for MAP and sous vide products”, in Fatber, J.M. and Dodds, K.L. (Eds), Principles of Modified-Atmosphere and Sous-Vide Product Packaging, Technomic Publishing Co. Inc., Lancaster Basel. 345-7.

- Stipanuk, D. (2019). Tourism and technology”, Tourism Management, August, 267-77.

- Tansey, F.S., Gormley, T.R., Bourke, P., O’Beirne, D. & Oliveira, J.C. (2019). Texture, quality and safety of sous vide/frozen foods. International Conference on Culinary Arts and Science, Orebro Sweden, 199-207.

- Thomas, C.J. & Brown, N.E. (2017). Use and cost of electricity for selected processes specific to a hospital cook-chill/freeze food-production system. Journal of Foodservice Systems 4(3), 159-69.

- Torres, R. & Skillicorn, P. (2020). Montezuma’s revenge–how sanitation concerns may injure Mexico’s tourism industry. Cornell Hotel and Restaurant Administration Quarterly 45(2), 132-44.

- Van Son, M. (2017). Oven technology: heat flux measurements as a tool for control. New Food 5(1), p. 51, 52, 55.

- Verboven, P., Scheerlinck, N., De Baerdemaeker, J. & Nicolai, B. (2018). Equipment considerations for sous vide food heating and cooling. Third European Symposium on Sous Vide, Katholieke Universiteit, Leuven Belgium, pp. 455-476.

- Williams, P. (2019). Vitamin retention in cook/chill and cook/hot-hold hospital food services. Journal of the American Dietetic Association 96, 490-498.

- Xie, G. (2018). Use of neural networks to predict roasting time and weight loss for beef joints. Food Service Technology 2(2), 35-52.